Arol presents a smart solutions for sustainable capping

- Publicado el 01 de Junio de 2023

On AROL booth at Interpack 2023, visitors were able to experience the latest capping technologies on product safety, a view on circular economy and on more sustainable packaging materials: spindles and heads for ROPP aluminum caps on glass and can bottles, smart instrumented bottles (wireless Bluetooth torque and top load tester for off and on-line dynamic measurements), decappers, decrowners. Furthermore, we’ll present tests on paper caps, thanks to the AROL LabV,a laboratory capper able to measure: approach angle, screwing stroke and angle, flat angle, total cam stroke.

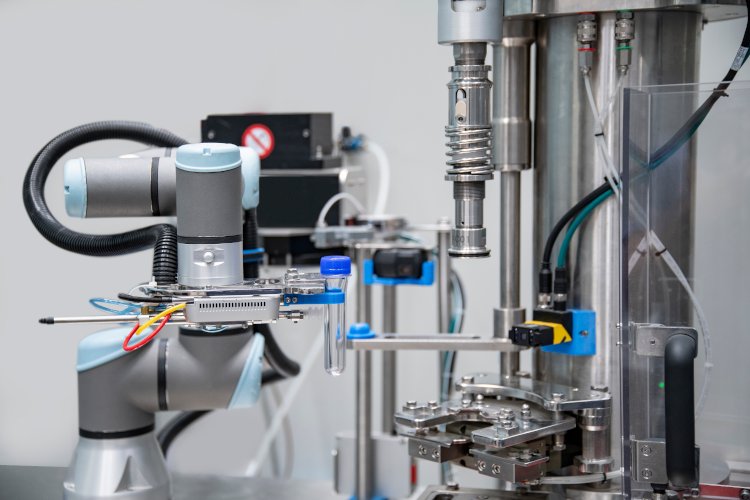

AROL also showed everything that can help bottlers in the using pet at its best from an environment point of view: from the laboratory phase –with the innovative robotic station ClosureXpertLab, where new ultra-light and/or tethered caps are tested, including extra-light bottles with different percentages of recycled plastic-to the caps feeding phase with visual quality control, up to the dedusting phase(pre-capping), and to the fully servo-controlled capping cycle(Equatorque IQ-EVO).

AROL capping technology is always in “motion”: it is based on special direct drive technology, completely software modelled. This approach led to high-end performances and allowed the implementation of a “Torque Virtual Sensor” and to a new non-invasive control of all the parameters of the capping head during its lifetime; New algorithmsare available for “positional approach” and “Application Angle Detection” at each capping cycle (AROL Thread Engage Technology); New sensors are developed for automatic non-invasive wear detectionof plastic rollers and for machine monitoringsuch us temperaturesand vibrationof critical parts or mechanical anomaly detection and prediction (AROL Node Sensors wireless technology).

High attention is dedicated to flexibility: for example, the possibility to manage different combinations of closures on the same machine, such as plastic threaded caps, crown corks and ROPP caps. Special attention is also paid to microplastics contained in the bottlesas well as to the complete quality control of the packaging, via RoboQCS and subsequent retroaction to the capper and to the entire closing process, to keep it stable and measured.

In other words, AROL introduced Smart Closure System, the innovative capping solution that guarantee efficient and proper closure application, ensuring product safety and saving materials, providing precise control over the entire capping process, increasing the overall equipment effectiveness, decreasingthetotal cost of ownership, extendingmachines’ life.